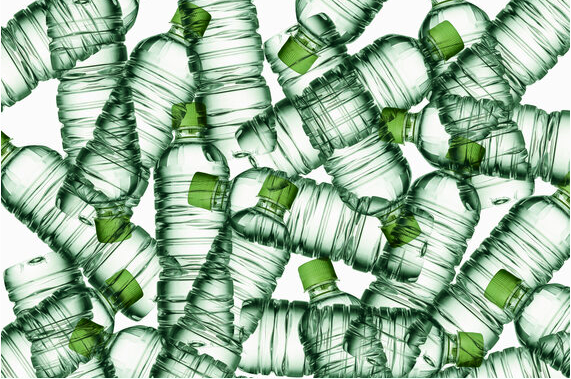

Plastic-free alternatives

Going plastic-free is easier than many people think: Thanks to modern alternatives to plastic products - made from renewable and recycled materials - out-of-home offers can already manage without plastic. In addition, ingenuity is also rewarded: there are some innovative possibilities for companies that go beyond mere plastic alternatives and improve their environmental balance in everyday life. Some restaurants even have their own vegetable gardens or self-managed composting cycles - cool ideas that go down well with customers. For the sustainable extra mile, regional and seasonal dishes are also a great option.

But what alternatives are there to plastic? What are the advantages and disadvantages of other materials? And how can they be used in the business? In this guide, we present five current plastic alternatives that make the switch to more sustainability a success.